Week 6 Progress

First and foremost, this week we found a new issue surrounding the mechanics of our proposed knee pad's contact with any flat surface. Basically when tested practically with a PLA (3D printing material), we observed that the impact on the bone is really hard and painful. To address this problem we plan to distribute shock impact. The thickness of the scales that will be used on the outside of the knee needs to be greater (larger height from the surface of the skin of an individual, protruding perpendicular outwards). To determine these exact measurements we wanted, we built a test pad, thus making it much more unlikely 3D prints would have to be run again, wasting materials. The heights which were decided were 0.5 cm for the region of the bone, 0.8 cm and 1 cm for the peripheral regions.

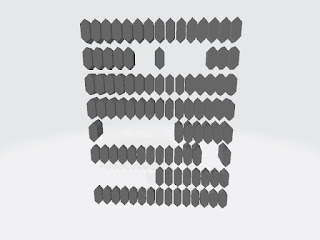

We also submitted our 3D print design of the hexagonal scales with three different heights. The designs are displayed below.

While we wait for this to be completed, we plan to begin working on all other parts of the knee pad, that being the straps to secure it to one's knee, and the side of the pad that will be in contact with one's skin to ensure comfort. This is possible to begin now that all the materials for this (glue, D3O pad, spray-on rubber, and Velcro straps) are gathered.

While we wait for this to be completed, we plan to begin working on all other parts of the knee pad, that being the straps to secure it to one's knee, and the side of the pad that will be in contact with one's skin to ensure comfort. This is possible to begin now that all the materials for this (glue, D3O pad, spray-on rubber, and Velcro straps) are gathered.

Comments

Post a Comment